Articles published in Swedish media. An english abstract is presented with each article. Please click on the picture for the full article in Swedish. Klicka på bilden för hela artikeln på svenska.

Media

Gas Unit prestudy

Mälarenergi is doing a pre study of a gasification unit installation. Because the gasification unit is to be installed and integrated with the existing CHP plant they have a need to map the existing installations where the connective pipes are to be drawn. Because of the size of the pipes to bi installed, up to one meter in diameter, it is important that the will really fit. Therefore a laser-scanning project is carried out, and the new pipes are then modelled in the resulting 3D-model. In this case the environment to be scanned was so tight that several separate point clouds had to be made and then put together using a series of total station measurements. In addition the laser scanners built in camera was used to put colour texture on the points, making it easier for the CAD modellers to make sense of the point cloud. Laserscanning is ideal for this type of project since it saves time compared to guessing the positions of the pipes from the old blueprints.

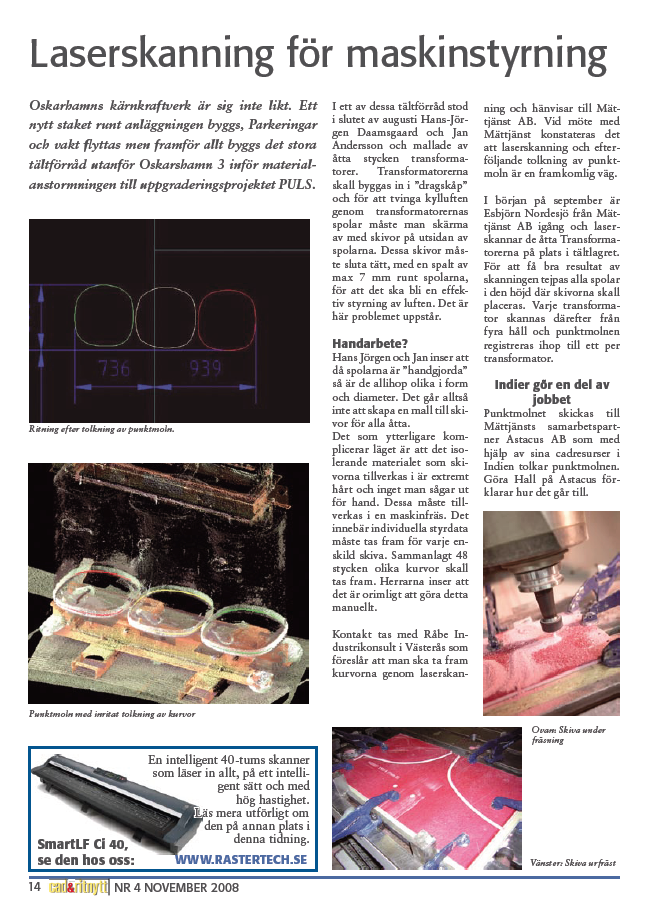

Laserscanning for milling

New transformation coils were to be capsuled at Oskarshamns kärnkraftverk. Unfortunately each transformer was individual and the capsules had to be crafted using computer-aided milling. This means that a computerised template had to be produced for each of the eight transformers, 48 eight different curves in total. The team soon realized that to do this by hand would be both time-consuming and costly and so laserscanning was used to depict all eight transformers. The point clouds were then used to produce the computerised templates for the computer-aided milling.

Remodeling and renovation

When renovating old attics and building new apartments inside them, contractors and architects face a huge challenge. Not only are the blueprints, if they exist, of the old houses only guidelines for how the house was built, in addition the house has had time to move during its existence, aging if you will. Peculiarities that gives the house character if you will, but a nightmare when prefabricating kitchens or planning plumbing and wiring. Ultimately the plans will often not coincide with reality, with costly delay and reworking as a consequence. Laser scanning is a way to get to the bottom of this problem. By first scanning the attic and then making a model or a blueprint based on the point cloud in Revit, architects can plan the apartment in harmony with the old house, and thanks to laser guidelines contractors can install everything where it belongs without the fuss of something not fitting in right.

Costefficient laserscanning

While laserscanning itself is beginning to go down in price as the cost of the technology decreases and competition increases the cost of post processing can still be high due to the high amount of man hours required. This article describes a few ways in wich the point cloud can be used without the need of excessive post processing.

Designing directly in the point cloud By using different plug-ins for CAD-software – for example Leicas Cloudworx for PDMS, AutoCad, Microstation or Smartplant – the point cloud can be handled in CAD without burdening the software itself. That makes it possible for the constructor to model directly in the pointcloud, or the documented reality if you will. The cons of this approach is that you are dependent on having a laserscanning of moderately high quality and of course the plug-in to handle point clouds. To open point couds directly in CAD-software without the plug-in is often impossible for point clouds of normal size. The benefit of using a point cloud with high point density is that you minimize the need for modelling and post processing the point cloud.

Using the point cloud as a control Another way of using a point cloud is to design based on existing documentation and blueprints and then making a control scan of the area. This scan can be made with lower point density, something that makes the fieldwork easier and less costly. The point cloud is then used for collision analysis, control and adjusting the model. This method of use requires no post processing of the point cloud.

Processing of the point cloud on different occations If you know that you are going to continuously work on retrofitting or changing a building or productionsite it can be cost efficient to let scan the whole building in the beginning of the process. This can also be necessary when you only have acess to the site during a limited period of time, such as maintanance shut downs in nuclear facilities. You can then later post process the point cloud as you go along, and only take the post processing cost when need arises. In order to make such a process cost efficient it is good if you have the ability to do the post processing yourself.

No plug-in? Today there are several examples of CAD-software that does not have any plug-ins to handle point cloud. In order to use it in the CAD environment you then have to mesh or model the point cloud. The post processing needed in order to do this has in the past been advanced and costly and usually required subcontracting. There are clear disadvantages doing this. There is a risk that the delivery is slow and incorrect as well as specifying a level of detail not needed, just to be on the safe side, something that affects the cost in a negative way.

Lately, however, software has been introduced that lets you do the post processing yourself. With such a software you can easily take the piece of the point cloud that you are interested in, export it, and then create a mesh in a generic format, such as STEP, that can be imported into the CAD environment that you are working in. The advantage is that you take the cost of processing when the need arises, in form of your own work hours spent. Furthermore you can descide for yourself during the process the level of detail needed and you don’t have to halt your construction work in order to wait for a delivery from someone else.

In conclusion; today it’s not always necessary to post process a point cloud in order to be able to use it, something that makes laserscanning even more useful and versatile.

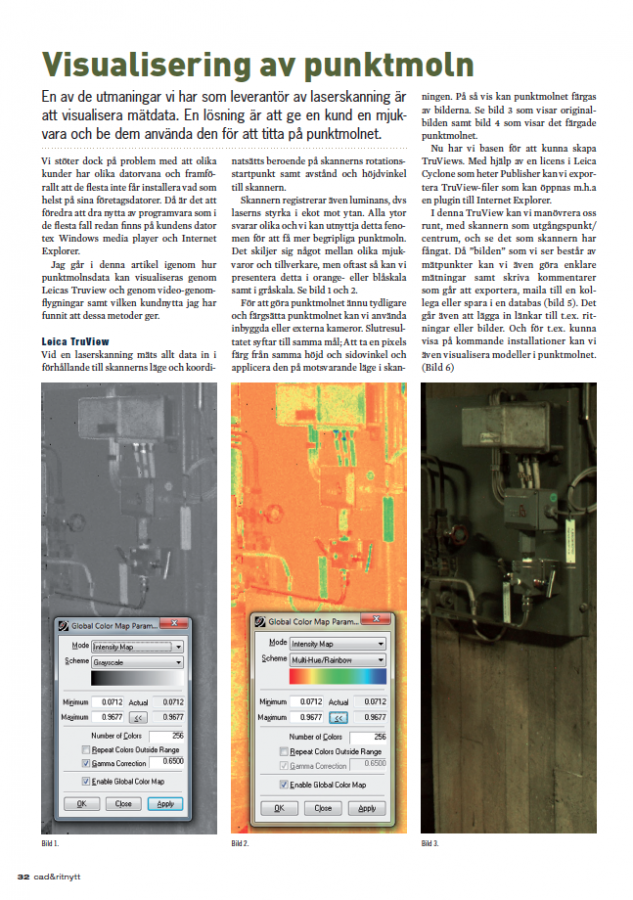

Point cloud visualization

One of the greatest challenges as a supplier is visualizing the data.

There are software to do this, however the clients have varying computer skills and are sometimes not allowed to install software themselves on company computer.

In that case it is a great asset to be able to use software already present on the lcients computer that they are familiar using, such as Internet explorer and Windows Media Player.

One option is to make use of Leicas TruView, where all the client has to do to view the data is to install a free browser plug in. TruView lets your client stand and rotate in each scanner position and gives a better feeling for the data, either using data on the computer hard drive or an online database should your client require that.

The client can also make measurements, draw simple geometric shapes and write straight on the TruView, notations that he or she can share with others in the projects as necessary. The TruViews are available in all the colour scales that your registration software uses, and if your scanner is equipped with a camera you can use that to imprint the real world colours on your scan. You can also make TruViews of point cloud data integrated with models, such as planned piping.

Another alternative is to make a flyby movie of the point cloud, this can in some cases work even better when explaining the project for example getting the personell working on site with no experience of reading blueprints to understand and evaluate the plans before the retrofitting begins. It is also a great way to show clients and management the planned additions.

Remodeling and renovation

When renovating old attics and building new apartments inside them, contractors and architects face a huge challenge. Not only are the blueprints, if they exist, of the old houses only guidelines for how the house was built, in addition the house has had time to move during its existence, aging if you will. Peculiarities that gives the house character if you will, but a nightmare when prefabricating kitchens or planning plumbing and wiring. Ultimately the plans will often not coincide with reality, with costly delay and reworking as a consequence. Laser scanning is a way to get to the bottom of this problem. By first scanning the attic and then making a model or a blueprint based on the point cloud in Revit, architects can plan the apartment in harmony with the old house, and thanks to laser guidelines contractors can install everything where it belongs without the fuss of something not fitting in right.